In a world where precision and efficiency reign supreme, custom CNC milling services are emerging as the vanguard of modern manufacturing. Gone are the days of one-size-fits-all solutions; todays industries demand tailored approaches that cater to unique specifications and challenging designs.

With advanced technologies at their fingertips, manufacturers are harnessing the power of Computer Numerical Control machining to produce complex, intricate parts with an unparalleled level of accuracy. This evolution is not just a trend; its a transformative leap that promises to redefine standards, streamline production processes, and reduce waste.

As businesses strive to remain competitive in an ever-evolving market, embracing custom CNC milling presents an opportunity to innovate like never before. Here, we explore how these specialized services are not only paving the way for the future of manufacturing but also reshaping the landscape of industries ranging from aerospace to healthcare.

What is CNC Milling? A Brief Overview

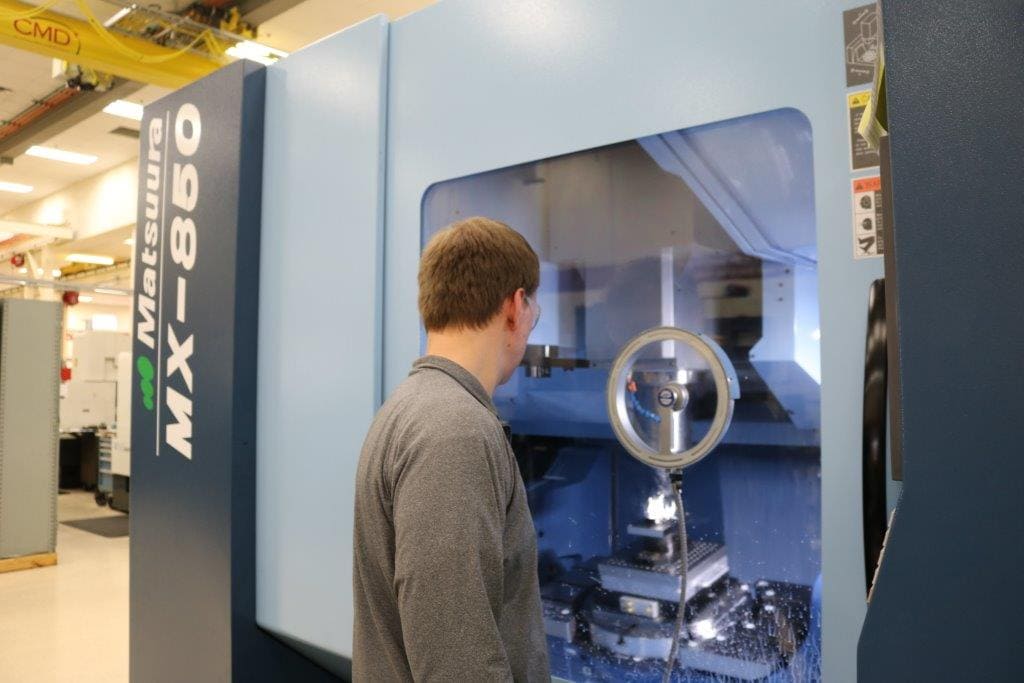

CNC milling, or Computer Numerical Control milling, is a cutting-edge manufacturing process that revolutionizes how materials are shaped and formed. This technique employs highly precise, automated machines to remove material from a workpiece, transforming solid blocks of metal, plastic, or wood into intricate components with remarkable accuracy.

Unlike traditional methods, CNC milling is driven by computer software that interprets digital designs, allowing for complex geometries and repeated consistency that manual machining simply cant match. Whether creating prototypes or high-volume production runs, CNC milling enables manufacturers to tailor their processes, optimize efficiency, and deliver custom solutions that meet specific design criteria.

In an era where adaptability and precision are pivotal, CNC milling stands at the forefront of modern manufacturing, paving the way for innovation and customization in various industries.

The Advantages of Custom CNC Milling Services

Custom CNC milling services offer a wealth of advantages that position them as a cornerstone of modern manufacturing. With unparalleled precision and flexibility, these tailored solutions can accommodate intricate designs and meet specific customer demands, ensuring that each component is crafted to the highest standards.

Imagine a workshop where creativity knows no bounds—where materials ranging from metals to polymers can be shaped with incredible accuracy. This adaptability not only enhances product quality but also reduces lead times, dramatically accelerating the production process.

Furthermore, the scalability of custom CNC milling means that whether you need a single prototype or a large batch of parts, these services evolve seamlessly to fit your project’s needs. Thus, businesses that leverage custom CNC milling find themselves at the forefront of innovation, ready to tackle the complexities of an ever-evolving marketplace.

The Impact of Automation in CNC Milling

The integration of automation in CNC milling has revolutionized the manufacturing landscape, ushering in an era characterized by unprecedented precision and efficiency. As machines take over repetitive tasks, they reduce human error, leading to a remarkable enhancement in product quality and consistency.

However, this shift doesn’t merely streamline processes; it also allows skilled workers to focus on more intricate design and programming aspects, fostering innovation in custom parts creation. Imagine a workshop where a fully automated CNC mill can churn out hundreds of complex components overnight, tirelessly repeating meticulous movements without fatigue.

This transformation is exhilarating—transforming one-off prototypes into scalable production runs with startling speed. The result? A dynamic industrial environment that thrives on agility and customization, positioning custom CNC milling services as the cornerstone of future manufacturing.

Conclusion

In conclusion, the evolution of manufacturing is rapidly embracing the advantages that come with custom CNC milling services. As industries strive for greater precision, efficiency, and adaptability in their production processes, the ability to create tailored components with intricate designs and high-quality finishes becomes increasingly vital.

This innovation not only meets the unique demands of diverse applications but also supports sustainability through the reduction of waste and resource consumption. As technology advances and businesses seek competitive edge, custom CNC milling services stand poised to redefine the landscape of manufacturing, paving the way for a more dynamic and responsive industrial sector.