There are so many various engraving companies out there that put a lot of effort into satisfying their clients’ needs. Some of them have special laser cutting and engraving machines, while others have more flexible and standard business models. However, the truth is that there are lots of industries that are taking advantage of this service. This is a very effective way of generating high-volume products in a short period of time.

Primarily, industries are relying on laser cutting services because they are trying to be inventors who create new prototypes. Laser cutting is providing a very high accuracy level, huge agility as well as sustainable quality features. Different engineers developers and entrepreneurs are trying to be innovative in the business world and to launch some new things that will solve current problems that particular industry is facing.

Since the competition is tough and it is very hard in today’s world to patent something innovative and popular, laser machines are the ones that are creating prototypes and offer reliable solutions. Let’s see some of the industries that are benefiting from laser cutting and engraving machines.

1. Automotive Manufacturing Industry

One of the many industries that are taking advantage of this service is the automotive one. In fact, they are relying on laser cutting on a huge level. Since all parts of cars and trucks need to be created precisely, manufacturers are needing laser cutters since no other existing machine has the ability to deliver that type of precise and high-speed efficiency. Not only that there are thousands of car parts, but primarily they are now created in the way to be as smaller and discreet as possible so they can look sophisticated.

Therefore, they need to be cut just into a specific shape and size with smooth edges. When it is compared to any other procedures, only the cutting laser procedure is the least wasteful. This factor is enabling companies to represent themselves as a sustainable manufacturer. Finally, the car industry is choosing this type of machine for their needs because they are much safer than other cutting tools.

2. Musical Instruments Industry

The precision of laser cutting machines is the crucial factor why this industry is choosing them instead of other cutting and engraving tools. Even though there are still many musical instruments that are hand-crafted, the number of those that are created by massive manufacturers is higher.

All musical instruments need to be developed precisely, so they can have a high-quality sound. In fact, even a small defect can compromise the frequencies of the instrument. No matter whether the instruments are electric or classic, they have components that are requiring very huge effort in the terms of cutting.

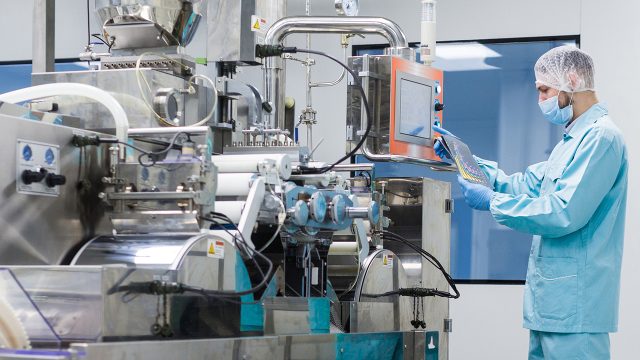

3. Medical Equipment Industry

Medical equipment manufacturing can never be able to reach this level of popularity and development if they are not using the advancements and benefits of laser cutting machines. This is the primary reason why we are now having such modern medical equipment that provides high-quality features.

Healthcare demands are bigger and bigger over time and a lot of effort is invested into inventing prototypes of new equipment that will make a significant change in the medical field. We are talking about life-saving equipment. As you probably noticed, medical devices are now getting very compact, smaller, yet a lot more effective, and with high-quality features. This is all thanks to the laser cutting machine’s precise characteristics.