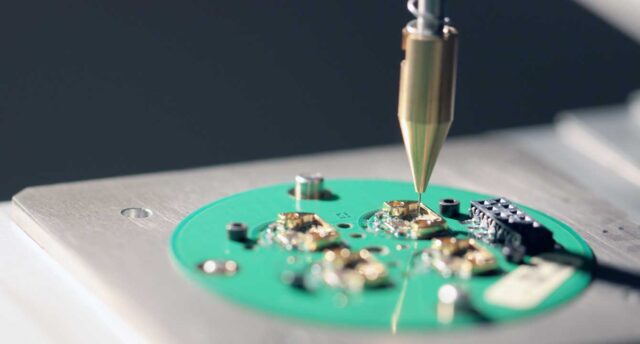

It is a series of services that include engineering design, production of PCBs, production of subassemblies and similar activities. Any company may use this contract to supplement or replace production operations. It is known that it brings many benefits to companies, and you can read more about it below.

What Is Electronic Contract Manufacturing?

With this move, companies significantly reduce supply chain costs. The main reason is the content of the service they can buy. ECM is a one-stop solution, as it includes design, PCB layout, component supply, and all other processes the company would go through. Now customers just need to give them ideas and delivery time. However, it is also the practice for clients to do research and development on design while leaving the rest of the work to ECM.

They procure components, products, assemble PCBs and more. In some cases, clients do the design themselves while hiring one ECM assembly company and another end product assembly company and others for after-product services. So, there are several ways companies can use ECM services.

History of the Electronic Contract Manufacturing

The industry developed many years ago, but first worked with smaller companies. Advances in technology have enabled the provision of better services, which has led to faster assembly of electronics. In the following years, manufacturers increasingly left the assembly to ECM.

In the early 2000s, ECM companies were largely buying assembly plants. We must mention that they are not only engaged in production but also in research and development in order to optimize the process of hardware production.

Advantages of the Electronic Contract Manufacturing

In the past, companies had to meet a large number of requirements in order to meet production needs. It required a high consumption of resources, a lot of effort, time and money. Fortunately, the ECM has emerged and automatically reduced production costs and increased efficiency. This has allowed companies to focus exclusively on product research and development. They can also track all their critical information, as they will use the ECM to manage documents much more securely. They will be centralized and easily searchable. Each document will be linked to the others, which means that the entire organization will be at a much higher level.

There are also advantages for end consumers, because they get a better service that your competitors cannot provide. Today, all companies are striving for digitalization, and one of the best ways to do that is the ECM solution. Less paperwork will provide you with more office space and more satisfied employees. This will reduce operating costs and save business tracking time. For example, if the data is not well organized, it is almost impossible to analyze it. You need a digital solution that will simplify the whole process and efficiently organize documents and increase productivity.

Conclusion:

This business model is equally good for both parties working together. So everyone benefits from electronic contract manufacturing. If you need advanced PCB production and assembly, the ECM is the right choice for you. We are sure that they will not let you down, because you will find all the solutions for your business in one place.