The most common methods used for the production and redesign of metals for different purposes are fiber and CO2 lasers. We have to mention that CO2 is much longer, with a tradition of over 50 years in different industries, while fiber technology is more recent, and its implementation started during the 90s.

If you have a production line and you are interested in remodeling and applying different materials, it is important to understand these options. While it might seem the same, there are some crucial differences between them.

Also, you will find many machines that you can use for these cutting processes, but it is important to choose ones introduced by well-known and reliable companies. Therefore, if you need co2 laser engraving cutting machine, a company like Wattsan is the best solution.

Moreover, since they don’t have the same abilities when it comes to power output, accuracy, and details, you should learn more about the required process and choose the right option. We are going to introduce you to some of the main features and differences between fiber and CO2 cutting technology.

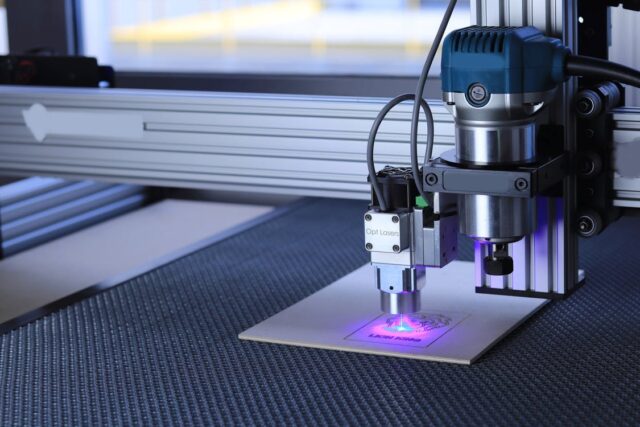

Main Features of Fiber Cutting

The main feature of fabric laser is that it is using radiation and converts it into energy that can cut through metal and other materials. The great advantage is that this process is highly efficient while it doesn’t need a lot of power. We also have to mention that fiber optics are used in other areas, like telecommunication and medicine.

For example, it is one of the most efficient options for internet cables since the speed is much faster when compared to other solutions. It all depends on the area and distance of the light that is going through the fiber. When the beam is focused on a small area and short distance, it can easily cut through metal with extraordinary precision.

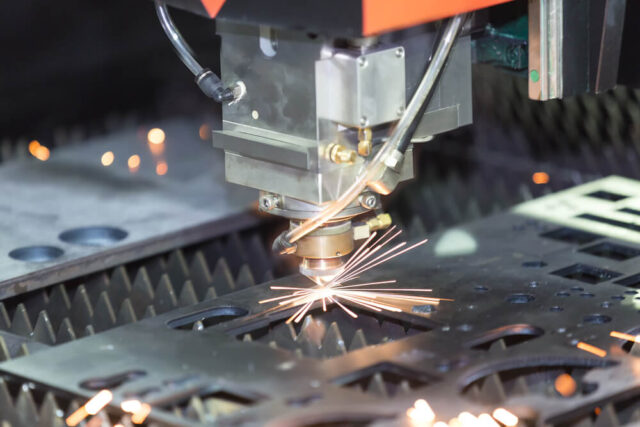

Main Features of CO2 Cutting

Since it is an older technology, it will be much easier for any company to find necessary equipment and cheaper to establish a production line as well. When it comes to the cutting process, the most important part is related to the gas used to create pressure that is high enough to cut through different materials. The pressure is made in combination with electricity.

As we already mentioned, this option is cheaper than fiber technology, which is one of the main reasons why it is used much more in different industries. Besides that, it is highly effective in medicine, engraving, and processing different materials.

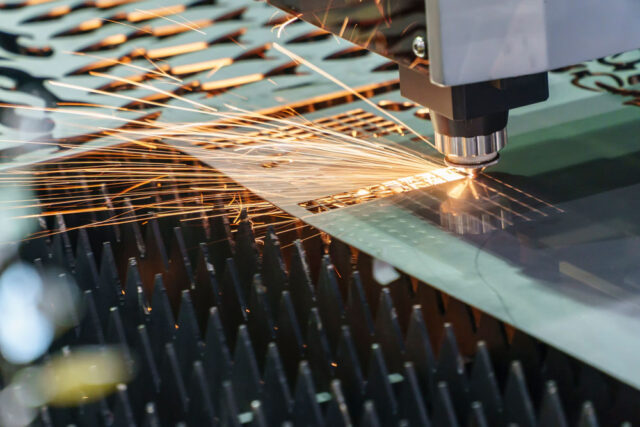

What Are the Differences?

The process where energy is created to cut through various materials is the core difference since the fiber is using the beam of light while CO2 machines are using a combination of gas and electricity. Another important difference is the required energy, which is much higher for gas cutting. Also, the accuracy of fiber is much higher since the beam can be limited to microscopic sizes.

On the other hand, the larger beam in CO2 machines can bring advantages in some processes where speed is in main focus. For example, when bigger surfaces require cutting, and there is no need for microscopic accuracy.

Another important feature is related to different materials and how they react to both of these options. For instance, CO2 is perfect for wood, leather, glass, stone, but it can be more difficult to cut through certain metals.

Still, there are special devices where that is possible as well. On the other hand, fiber is perfect for metals like aluminum, copper, and more, but cutting the non-metal surfaces can be challenging. Both of these options are excellent for steel, aluminum, and copper, while you should use CO2 for plastic, stone, and textile.

Furthermore, the amount of details that have to be applied to some material is also an important factor, along with the speed and power output. For instance, fiber can cut through aluminum five times faster than the other solution. On the other hand, the process will be faster with Co2 when you are processing steel.

In case you need a cutting machine so you can apply various details on some product, complexity of those details is an important factor. Fiber technology will allow you to add much more dertails on some materials. On the other side, the main downside is the price of devices and additional expenses related to maintenance and required equipment.

The thickness of the material that you need to process will also make a difference, and Co2 is a much better solution if you need to cut through thicker surfaces. Also, this option is faster, more powerful, and more affordable, which are the main reasons why it is still much more common when compared to another option.

When it comes to maintenance, it is more complicated for Co2 machines since you will have to deal with the replacement of gas, cleaning, and other challenges, while fiber devices are easier to keep in good condition. Also, fiber cutting is much safer, while it is essential to have experienced people working with Co2.

Last Words

There is no need to choose between these two options as an alternative to one another. It should depend on the products you are making when it comes to making the right choice.

Therefore, if you need high precision and you are processing metals like copper, aluminum, and steel, fiber is perfect if you want to create thinner and high-quality pieces with high-end details.

On the other side, processing the non-metal materials and thicker surfaces can only be done with an option that is using gas and electricity. In that matter, be sure to learn about both of these options and determine the features of materials that you are planning to process before you decide to invest in any of these two cutting technologies. Both of them can be highly efficient, but only on certain materials, and only by learning more about them will help you to make the right choice and avoid mistakes.